Invention and Innovation

Benebici benefits from numerous US and foreign patents, several issued and others pending, relating to our unique front wheel drive technology. This technology allows full-time pedal drive to the front wheel while steered over a wide angle. It also prevents pedal power generated by strong leg muscles from interfering with steering controlled by less powerful arms. This and other key innovations allows Benebici the honor of world’s first practical cycle transmission comprising entirely polymeric gearing. Many of us think “cheap” when we hear “plastic,” but gear-grade polymers have several important advantages compared to metal. Plastic gears are quieter, more tolerant of imperfections, do not require lubrication, wear better and spin more easily than conventional metal gears. Unfortunately they aren’t nearly as strong. Benebici works by controlling damaging powertrain forces while transmitting necessary drive power. These innovations permit the obvious-yet-unusual configuration of this bike, because they permit us to simultaneously steer a front wheel and drive it by a frame-mounted pedal crank.

About the Trunk and the Great Outdoors

Folks may have concerns about a vehicle with a wooden trunk. However we may judge the design on form and function, most people do appreciate the aesthetic quality of natural wood. We commonly experience clear-finished wooden objects in our daily experience as indoor furnishings, and this seems for good reason. Witness the rapid destruction of indoor furniture exposed to outdoor weather: varnishes check and flake, wood cracks and warps, glue crumbles and dissolves. Although wood is perhaps mankind’s most versatile building material, Benebici may appear ill-conceived.

Since Benebici exists to bring car-like utility to a bike platform, to narrow a century of divergent evolution, we looked to automotive history for guidance. Until roughly a hundred years ago, auto bodies were wood-framed and sometimes fabricated with wooden panels instead of steel. In later decades, clear-finished, wood-bodied station wagons remained as exclusive luxury items that inspired fake wood trim on steel bodied cars. Wood bodied cars were exclusive luxury items because they were painstakingly handmade by highly skilled craftsmen, i.e., exorbitantly expensive. Today’s computer-controlled machines can cut and shape wood parts with greater accuracy and less sweat than the craftsmen of yore. We can assemble well designed, precisely fitted, curvaceously 3D objects of wood much like other, commonly mass-produced materials. We hope the marketplace values the skillfully hand-finished product just the same as before, though.

Like shingles on a roof, Benebici employs layered strategies to exist outdoors as well as indoors. Modern adhesives, sealants, and paints have dramatically improved the weather-ability of wood used outdoors. Benebici’s trunk is constructed of a sturdy whitewood frame, securely glued and screwed together, with thin, marine-grade plywood panels caulked in-between. Marine-grade spar varnish is used to seal and finish the frame and panels before assembly caulking. This makes the trunk box durable in service, weatherable outdoors, and repairable when damaged. (It’s also lightweight: the complete, finished trunk box weighs only 22 pounds.) The roll-top is uniquely constructed to be both rain-proof and strong, unlike the traditional furniture pieces it resembles. For severe weather or prolonged outdoor storage, a form-fitted tarpaulin quickly snaps in place over the rear. Of course, as with any other bike, sheltered storage is always recommended when possible. At 30 inches wide and 6 foot 9 inches long, Benebici is able to pass through a standard exterior doorway or narrow aisle, and so can utilize available shed, carport, veranda, lanai, or sun room space, besides garages or living areas of higher beings.

About the Batteries and their Purposes

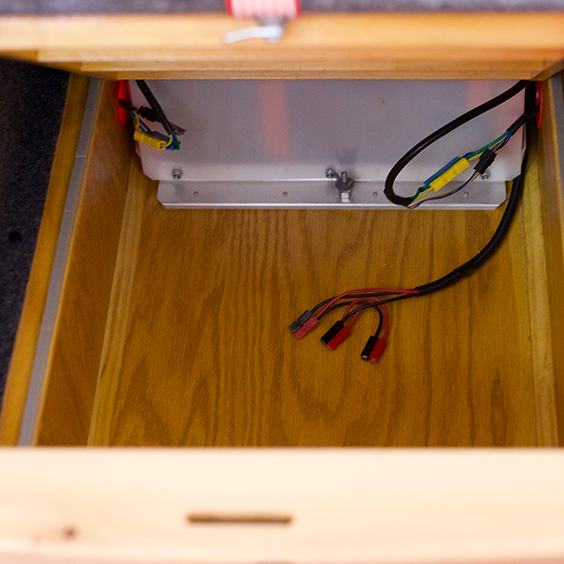

Benebici uses three 12V batteries of the sealed lead-acid, absorbed glass mat (SLA-AGM) type, containing 1 kWh of energy. This technology is safe, clean, ubiquitous, relatively inexpensive, available at retail off-the-shelf, rechargeable by commonly available means, and is both made and recycled in the USA. (Unlike many “recyclable” substances, lead recovered from depleted car batteries has long been essential to the economics of new battery manufacturing.)

Lithium-ion battery technology is widely viewed as more modern and superior for most applications, due to higher volumetric energy density and lower mass density compared to lead-acid. It is unfortunately disadvantaged by a lack of consumer market standardization in kilowatt-hour battery sizes, and a fundamental chemistry with notorious stability problems that requires sophisticated computer controlled maintenance. Big Li-ion batteries and chargers, like nuclear reactors, must be meticulously engineered and built for vehicle applications. (Ask Boeing about that.) While the discharge cycle life is much higher than lead-acid, the initial cost of Li-ion batteries and chargers is much higher as well, and safe replacement batteries or chargers may be difficult to obtain in the future. The useful life of correctly applied lead-acid batteries is typically in the hundreds of full-discharge cycles, meaning that one may expect over a year’s worth of heavy, daily use, and the cost per use is otherwise comparable to Li-ion.

Of course, off-the-shelf accessory items for automotive use are automatically suitable for Benebici, since 12V vehicle electrical systems operate the same charge and discharge voltage environment. Although Benebici’s motors are driven by 36 Volts of three 12V batteries connected in series, the 12V output of a single battery is available for on-demand accessory use also, even while recharging. Accordingly, a 12V “cigarette lighter socket” type receptacle is provided for use whenever interior trunk access is allowed.

In the case of Benebici, the AGM batteries provide roughly 100 pounds of mass in a small volume below axle height, allowing the rider to sit well above axle height with a reasonably low center of gravity for stability in cornering. Of course we could achieve the same result using a larger volume of lighter, more expensive batteries, or by carrying ballast stones or sandbags. Is it too much to call “lead but not dead” weight the elegant solution here?

About the Seats, Benebici’s and Yours

Nearly all wheeled passenger carrying vehicles of the last hundred years have two “suspension” elements in common: pneumatic tires and cushioned seats. These springy devices serve to isolate the vehicle passengers from bumps and bruises otherwise inflicted on contacting body parts. Motor vehicles usually also have chassis suspension springs connecting the heavy vehicle structure to the road wheels. Besides improving the comfort and safety of passengers and cargo, and making four-wheeled vehicles controllable, the chassis suspension also protects the vehicle structure by controlling the forces unleashed when the large vehicle inertia meets an immovable road surface obstacle (for other obstacles there are bumpers.)

Conventional bikes don’t have chassis suspension because they have very low inertial mass, including a rider, compared to the strength of their frame structures, and because chassis suspensions add unwanted weight to vehicles propelled soley by meager human power. Road bike riders know that while soft tires and springy saddle seats are helpful, smooth pavement and vigilance against obstacles is the key to comfort, if not survival.

Benebici has a suspension system between conventional bikes and motor vehicles to suit our particular hybrid configuration. All three road wheels wear high-quality, medium-pressure tires for smooth rolling and road shock absorption. We use a strong but relatively lightweight frame of “chromoly” steel, the first choice of many cyclists, to bear heavy loads and flex without bending or breaking. The frame geometry and material further soften the ride. The robust steering fork is further protected by a “knee action” suspension. Above this sits the rider on an upholstered, full-width, flexible polyolefin seat suspension spanning sturdy bottom and back rest frames. This seat suspension is firm enough to support a pedal pusher without “Venus flytrapping”, yet flexible enough to absorb vibrations. Importantly, it can be cleaned with a tissue, cloth, or fire hose equally.

Last but certainly not least is the seat upholstery, a double-sided, reversible cushion securely attached to the seat frame by “hook and loop” tabs. The prototype seat is blue cotton denim on one side, faux leather microfiber on the other, the sides buttoned together through a layer of polyester fill. This construction is easily machine washable and enhances the comfort of the flexible seat suspension without unduly impairing pedal drive capability. It also keeps the folding seat assembly thin and lightweight, allowing easy removal for storage almost anywhere, including inside the locked trunk.

About those Unusual Pedals

We didn’t set out to reinvent the bicycle pedal crank any more than we set out to reinvent the bicycle wheel. By appearances, it’s clear that conventional wheels carried through, and conventional pedals didn’t. Here’s why.

The conventional bike riding posture puts the pedal crank below the hips of casual riders so that feet tend to rest on the pedals, working or not. Friction between shoes and pedals is only necessary to keep the feet in place while working. Otherwise, free sliding is tolerable if not desirable. The conventional paradigm requires the user to bring appropriate footwear. This means pedal contact surfaces can be relatively hard and long-wearing, and so foot pedals are conventionally considered as permanent parts of the machine. Compare this with hand grips of softer, energy-absorbing materials that wear out but are easily replaced: conventional users may not bring appropriate “handwear”.

In the semi-recumbent, feet-forward riding position, the legs are extended forward of the hips, and the feet rest on the pedals at an angle to the ground. Gravity works relentlessly to pull the feet off the pedals, so recumbent bikes have a unique problem. A common solution attempt is the use of heel slings under pedals to support the feet at rest. Even after painstaking adjustments, this function interferes with normal foot and ankle joint movement when pedaling, causing annoyance.

More friction between the pedals and feet can hold them together in place by leg weight alone. High-friction pedal materials work well, but they are generally softer and, like soft hand grips, will wear out and need to be replaced occasionally. Benebici employs pedals with soft, high-friction surfaces that can be easily replaced when needed.

Another particular problem unique to recumbent cycles is the extreme forward position of the pedal crank during inevitable collisions with environmental objects. For conventional cycles, collision with the ground is the main hazard for pedals, and conventional strategy is to make the permanent pedals strong enough to inflict more damage to the ground than vice-versa. For recumbent cycles with elevated, forward pedals, contact with delicate obstacles like beings and their property is more likely. A gentler strategy is desirable.

To minimize damaging effects to all parties, it’s desirable to let the pedals take the brunt, and to make them easily corrected afterwards. Benebici’s pedals are thus strategically designed to control collision damage. The unusual triangular shape eliminates useless outside corners of conventional, rectangular bike pedals and replaces them with smoothly tapered flanks. The pedals are themselves molded of a low-cost, impact-resistant plastic, cushioned with a soft rubber surface, easily snapped into place on a pedal crank shaft. When struck at any angle, they are designed to absorb collision energy by flexing and even popping loose before causing damage to other parts. Of course, this also makes them simple to replace and renew when worn by heavy use.

Benebici’s large triangular pedals with soft rubber covering have another purpose: they are humanity’s first bike pedals that are as comfortably used barefoot as with shoes worn. Not only does the soft rubber surface provide the pressure-reducing comfort of a shoe insole, but the pedal is long enough to allow un-shod toes to naturally and comfortably balance forces around the pedal axis under the ball of the foot, unlike a smaller conventional bike pedal that requires an overhanging shoe sole for toe support. This offers another choice for casual riders wearing casual footwear not ideal for cycling, like sandals, loafers, or flip-flops: take them off! Benebici’s handy storage net under the seat holds useless footwear until needed again.

Meets US Federal e-bike standards and safety regulations

Standard frame accommodates rider heights between roughly 5' to 6'4"

Weather resistant design for continuous outdoor use

Standard components:

More to Follow

The prototype seen here is simplified in a few ways: